Alberta Zero Emission Truck Electrification Collaboration (AZETEC)

Explore AMTA’s collection of corporate documents and reports. Here, you’ll find detailed records that highlight our organization and the initiatives we undertake to support and strengthen Alberta’s commercial transportation industry.

These resources offer valuable insight into how AMTA operates and the impact we make across the province.

Stay informed and connected with AMTA.

Transitioning Heavy Duty Trucking in Alberta: Magnitude of the Challenge

Transitioning Heavy Duty Trucking in Alberta: Estimating the Cost and Source of Funds

The Transition to Net-Zero of Heavy-Duty Road Freight in Alberta: A Scenario Model

The Alberta Zero Emissions Truck Electrification Collaboration

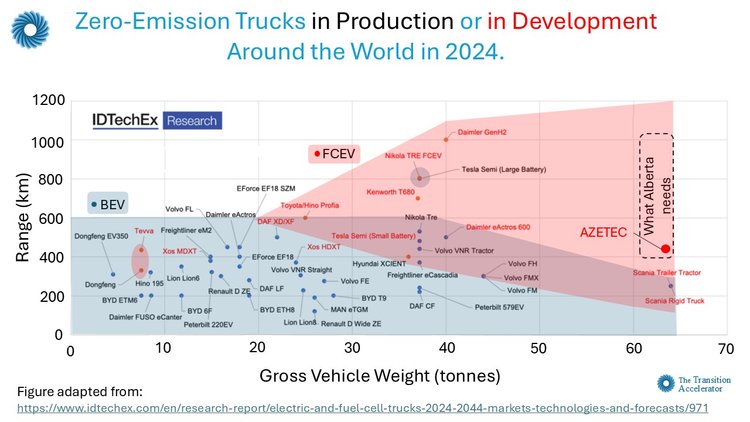

The Alberta Zero Emissions Truck Electrification Collaboration (AZETEC) is a first-of-its-kind industry-led project that will involve the design, manufacture, and testing of two long-range heavy-duty hydrogen fuel cell (FCEV) trucks for operation year-round on Alberta’s QEII, between Calgary and Edmonton.

AZETEC is a collaboration of 16 stakeholders within the energy, technology and transportation sectors that see significant opportunity in partnering to develop hydrogen as a low-carbon, low-cost transportation fuel that can drive substantial economic, environmental, and other societal benefits for their industries and for Alberta.

AMTA is collaborating our project partners to design and build two, hydrogen FCEV Class-8 trucks. These 64–tonne, B-train tractor-trailers, capable of traveling up to 700 kilometers between refueling and supporting Canadian weights of 63,500 kilograms, will be the first vehicles of this size and capacity built and tested in the world. They will be able to accommodate the loads, distances, and climate demands of the prairies. The primary focus of this initiative is on moving freight in Alberta’s geographical and climatic conditions while reducing greenhouse gas emissions and spurring a hydrogen economy.

AZETEC is the first step toward future large-scale deployments of hydrogen-powered heavy-duty freight vehicles in Alberta, in coordination with strategically located hydrogen supply and distribution systems. These on-road demonstrations will help identify industry barriers and strategies (including revised training to ensure safety) that will play an integral role in advancing Canada’s 2050 net-zero emissions goals.

The Alberta Motor Transport Association (AMTA) is leading this $17,257,323 million, several year long project, which includes an Alberta a government contribution of $7.3 million from Emissions Reduction Alberta (ERA). AZETEC is one of the projects selected through the ERA’s BEST Challenge, a $100-million funding opportunity for biotechnology, electricity, and sustainable transportation innovations. The total value of these new clean technology projects is $600 million.

Fuel Cell Electric Vehicle

While fuel cells may not be brand new, their potential use in commercial transportation in Canada is. The two heavy duty trucks that are being manufactured for the AZETEC project are the first of their kind due to size and capacity, and the working partnerships.

Components of note include the Freightliner glider, Dana electric drive components, and Ballard fuel cell module. The trucks will also include an onboard hydrogen fuel storage system.

Fueling Infrastructure

The AZETEC Truck Fueling Solution

Hydrogen (H2) for the AZETEC Project will come from an industrial gas supplier in Alberta that makes H2 using natural gas and steam-methane reforming (SMR) technology. This merchant H2 will be transported via tube trailer to the truck fueling station location, where HTEC will put it through an onsite purification and compression process to make it ready for truck refueling.

The Process

Industrial gas suppliers deliver hydrogen by tube trailer to the AZETEC Project fueling site. The H2 is at a pressure of 180 bar (2,600 psi).

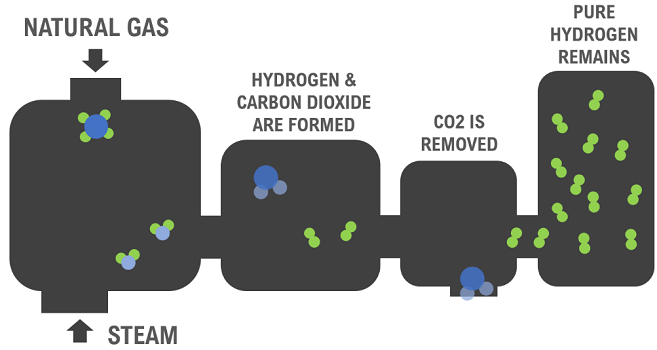

Making Hydrogen From Natural Gas

Most hydrogen today is made by steam-methane reformation of natural gas. It’s a safe, cost-effective, and efficient process where methane (CH4) —the main component in natural gas—reacts with high-temperature steam (usually in the presence of a catalyst) to separate the hydrogen from other molecules.

Project Objectives

- Guide technology to fit with the unique demands of transportation in Canada

- Heavy weights

- Long distances and cold weather

- Put Canada’s trucking sector on a zero-emission pathway

- Credible and compelling

- Well-to-wheel emission reduction

- Kick-start a Canadian hydrogen economy

- Decarbonize many other sectors

- Substantial economic and employment opportunities

- Leverage regional natural resources and capabilities

Features

- Two H2 fuel cell electric trucks

- Heavy Weight (63.5t)

- 700km Range (Edmonton to Calgary) between refueling

- Zero Tailpipe Emissions

Industry Led

- By Alberta carriers under real world conditions

H2 Produced from Alberta Natural Gas

-

Steam Methane Reformed

-

Cascade Refueling

-

Estimated 25% well-to-wheel emissions reduction

-

Carbon capture and storage planned for future phases

AZETEC Partners

Funding Support

Vehicle Design, Components and Manufacturing

Research, Greenhouse Gas Accounting and Commercialization

Infrastructure and Operations